About us

We started our gear manufacturing business in 1998 manufacturing

moulded

plastic gears and

moulded

plastic cases plus CNC metal

case.

We also design

moulding

and making mould by CNC machine with +/-0.02 mm cutting precision.

We gained expertise working in this market which better enabled us to understand

our customer¡¦s needs that often used similar technologies to manufacture their

optimized products, from 2005 we started cooperation with RC market for top

competitive application products.

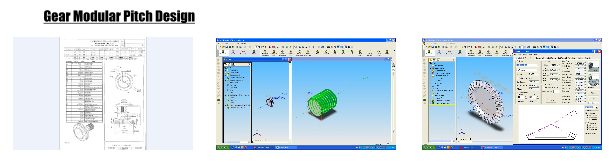

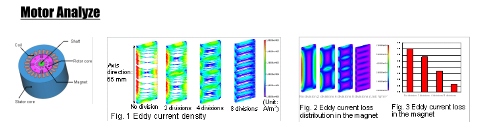

This included use of enhanced motor efficiency and making advanced gear box with

precision gears (diameter +/- 0.02) by 0.2 module ratio. We then

focussed

development of servos for the RC hobby market, our innovations in performance,

durability and compact design quickly drew the attention of the industrial

actuators market as well.

This has been achieved by meeting our customers' demands of maximizing torque,

speed and efficiency, while maintaining high reliability and durability and at

the same time minimizing volume/weight. Basically, we make high performance

servos.

It is our target to develop higher technology products and put our knowledge of

material and parts in different products to create best products for the

application.

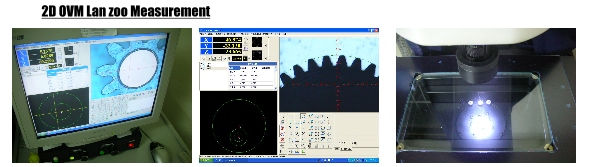

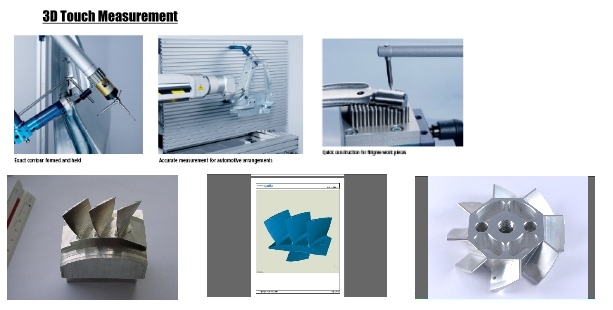

We

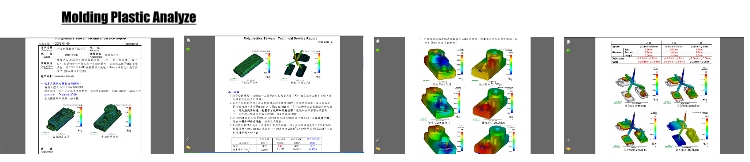

analyse

all components of finished products including motor characteristics used in

our servos, and double check quality of our

mouldings

using a 3D touch QC measurement system.

As we design new products we write R&D reports to follow and track details

by SGS Certification ISO 9001 rules.

We evaluate the market requirements, design product using CAD systems drawing 3D files prior to manufacturing the product for demo.

¡@

Copyright (C) 2004~2009 by Alturn USA cooperation,. All Rights Reserved.